1. Ukuhlolwa kwethiyori nokuhlaziya

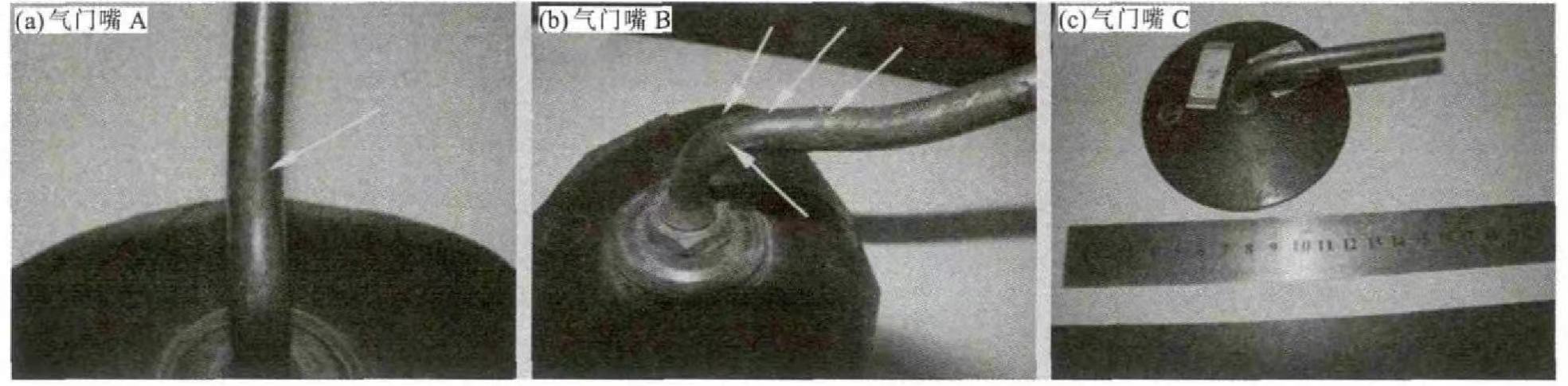

Kwezi-3ama-valve amasondoamasampula ahlinzekwe yinkampani, ama-2 angamavalvu, kanti u-1 uyisivavu esingakasetshenziswa. Ku-A no-B, ivalve engakaze isetshenziswe imakwe njengempunga. Umfanekiso Ophelele 1. Ingaphezulu levalvu A alishoni, ingaphandle levalvu B ingaphezulu, ingaphandle levalvu C ingaphezulu, kanti ingaphandle levalvu C ingaphezulu. Ama-valve A no-B ambozwe ngemikhiqizo yokugqwala. I-valve A no-B iqhekekile lapho kugoba khona, ingxenye engaphandle yokugoba ihambisana nevalvu, umlomo wendandatho ye-valve B uqhekekile ngasekugcineni, futhi umcibisholo omhlophe phakathi kwezindawo eziqhekekile ebusweni be-valve A umakiwe. Kusukela kulokhu okungenhla, imifantu ikhona yonke indawo, imifantu mikhulu kakhulu, futhi imifantu ikhona yonke indawo.

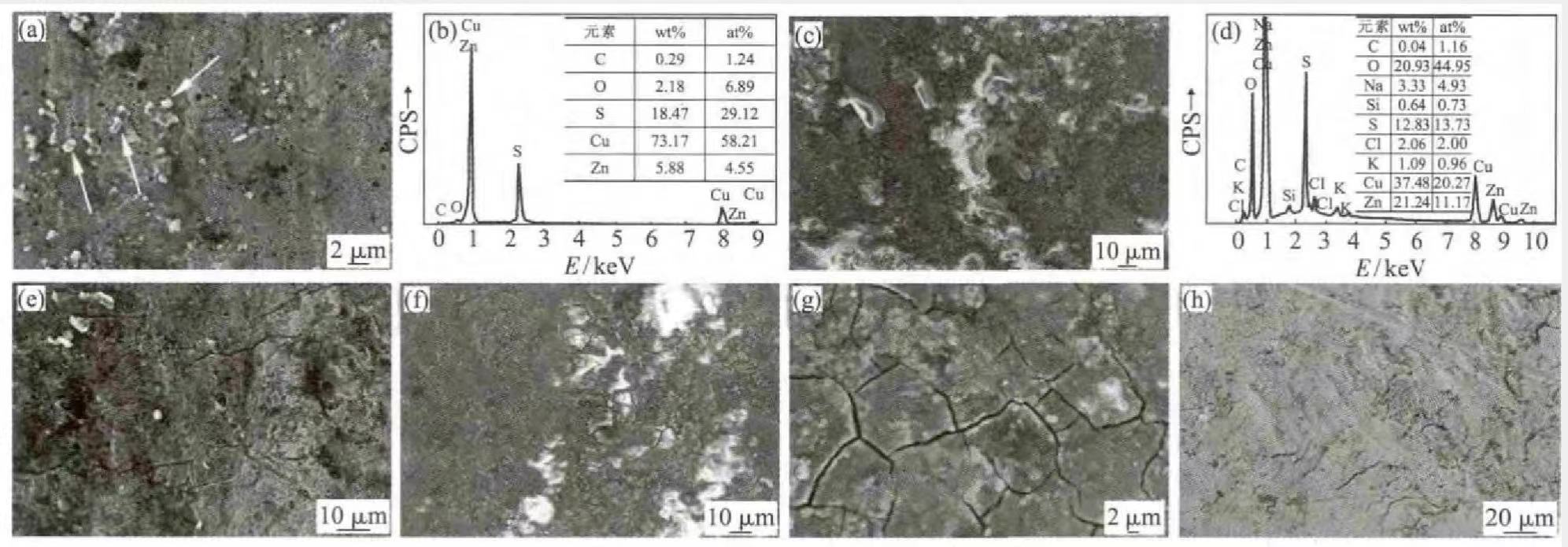

Ingxenye yei-valve yesondoAmasampula A, B, kanye no-C asikwa ejikeni, futhi i-morphology yangaphezulu yabonwa ngesibonakhulu se-electron yokuskena i-ZEISS-SUPRA55, futhi ukwakheka kwendawo encane kwahlaziywa nge-EDS. Umfanekiso 2 (a) ukhombisa ukwakheka kwe-microstructure ye-valve B surface. Kungabonakala ukuthi kunezinhlayiya eziningi ezimhlophe nezikhanyayo ebusweni (okuboniswa imicibisholo emhlophe emfanekisweni), futhi ukuhlaziywa kwe-EDS kwezinhlayiya ezimhlophe kunokuqukethwe okuphezulu kwe-S. Imiphumela yokuhlaziywa kwe-spectrum yamandla yezinhlayiya ezimhlophe iboniswa kuMfanekiso 2 (b).

Izibalo 2 (c) kanye (e) ziyi-microstructures engaphezulu ye-valve B. Kungabonakala kuMfanekiso 2 (c) ukuthi ingaphezulu licishe limbozwe ngokuphelele yimikhiqizo egqwalile, kanye nezakhi ezonakalisayo zemikhiqizo ebolayo ngokuhlaziywa kwe-spectrum yamandla ikakhulukazi ihlanganisa i-S, Cl kanye no-O, okuqukethwe kuka-S ezindaweni ezingazodwana kuphezulu, futhi imiphumela iboniswa uhlaziyo lwe-dg. Kungabonakala kuMfanekiso 2(e) ukuthi kukhona imifantu emincane eduze kweringi yevalvu ebusweni bevalvu A. Izibalo 2(f) kanye (g) ziyi-surface micro-morphologyes yevalvu engu-C, ingaphezulu liphinde limbozwe ngokuphelele yimikhiqizo yokugqwala, futhi izakhi ezibolayo zihlanganisa u-S, Cl kanye no-O, afana noMfanekiso 2(e). Isizathu sokuqhekeka singase sibe ukuqhekeka kwe-stress corrosion (SCC) kusuka ekuhlaziyweni komkhiqizo wokugqwala endaweni ye-valve. I-Fig. 2 (h) futhi i-surface microstructure ye-valve C. Kungabonakala ukuthi indawo engaphezulu ihlanzekile, futhi ukwakheka kwamakhemikhali okungaphezulu okuhlaziywa yi-EDS kufana nalokho kwe-alloy yethusi, okubonisa ukuthi i-valve ayigqwali. Ngokuqhathanisa i-microscopic morphology kanye nokwakheka kwamakhemikhali kwezindawo ezintathu zamavalvu, kuboniswa ukuthi kunemidiya egqwalayo efana no-S, O kanye ne-Cl endaweni ezungezile.

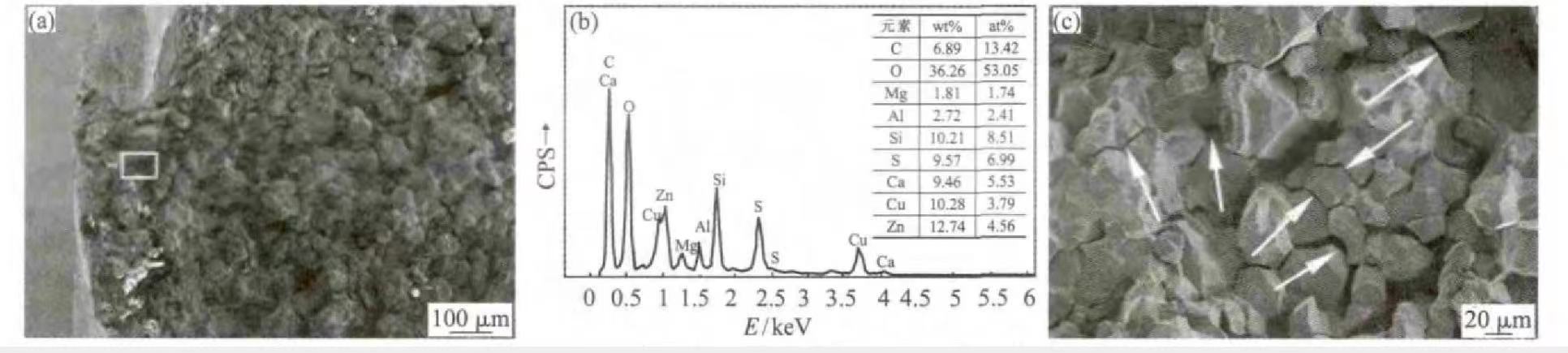

Ukuqhekeka kwe-valve B kwavulwa ngokuhlolwa kokugoba, futhi kwatholakala ukuthi ukuqhekeka akuzange kungene esiqeshini esiphambanayo se-valve, kuqhekeke ohlangothini lwe-backbend, futhi akuzange kuqhekeze ohlangothini olubhekene ne-backbend ye-valve. Ukuhlolwa okubukwayo kwe-fracture kubonisa ukuthi umbala we-fracture umnyama, obonisa ukuthi ukuphuka kuye kwagqwala, futhi ezinye izingxenye ze-fracture zinombala omnyama, okubonisa ukuthi ukubola kubi kakhulu kulezi zingxenye. Ukuphuka kwevalvu B kubonwe ngaphansi kwesibonakhulu se-electron yokuskena, njengoba kukhonjisiwe kuMfanekiso 3. Umfanekiso 3 (a) ubonisa ukubukeka okukhulu kokuqhekeka kwe-valve B. Kungabonakala ukuthi ukuphuka kwangaphandle eduze kwe-valve kuye kwambozwa yimikhiqizo yokugqwala, futhi kubonisa ukuba khona kwemidiya egqwalayo endaweni ezungezile. Ngokusho kokuhlaziywa kwe-spectrum yamandla, izingxenye zamakhemikhali zomkhiqizo wokugqwala ngokuyinhloko yi-S, Cl no-O, futhi okuqukethwe kwe-S no-O kuphakeme kakhulu, njengoba kuboniswe ku-Fig. 3 (b). Ngokubheka indawo ephukile, kutholakala ukuthi iphethini yokukhula kwe-crack ihambisana nohlobo lwekristalu. Inani elikhulu lokuqhekeka kwesibili lingabonakala futhi ngokubheka ukuphuka ekukhuliseni okuphezulu, njengoba kukhonjisiwe kuMfanekiso 3(c). Imifantu yesibili imakwe ngemicibisholo emhlophe emfanekisweni. Imikhiqizo yokugqwala namaphethini okukhula kokuqhekeka endaweni ephukile futhi ibonisa izici zokuqhekeka kokugqwala kwengcindezi.

Ukuphuka kwevalvu A akukavulwa, susa ingxenye yevalvu (okuhlanganisa nendawo eqhekekile), gaya futhi upholishe ingxenye ye-axial yevalvu, futhi usebenzise i-Fe Cl3 (5 g) +HCl (50 mL) + C2H5OH (100 mL) isisombululo, futhi isakhiwo se-metallographic kanye ne-crack growth morphology yabonwa nge-Zeispserver Aximtical Aximoscopy Umfanekiso wesi-4 (a) ubonisa ukwakheka kwe-metallographic yevalvu, okuyisakhiwo sesigaba esikabili esingu-α+β, futhi u-β ulungile futhi uyimbudumbudu futhi usatshalaliswa ku-α-phase matrix. Amaphethini okusabalalisa imifantu emifantwini eyindilinga aboniswa kuMfanekiso 4(a), (b). Njengoba izindawo zokuqhekeka zigcwele imikhiqizo yokugqwala, igebe phakathi kwezindawo ezimbili zokuqhekeka libanzi, futhi kunzima ukuhlukanisa amaphethini okusabalalisa imifantu. i-bifurcation phenomenon. Imifantu eminingi yesibili (emakwe ngemicibisholo emhlophe emfanekisweni) nayo yabonwa kulokhu kuqhekeka okuyinhloko, bheka umdwebo 4(c), futhi le mifantu yesibili yanda ngokuhambisana nokusanhlamvu. Isampula ye-valve eqoshiwe yabonwa yi-SEM, futhi kwatholakala ukuthi kunemifantu eminingi emincane kwezinye izindawo ezihambisana nokuqhekeka okukhulu. Lawa ma-micro-cracks avela phezulu futhi anwebeka aze afike ngaphakathi kwevalvu. Imifantu yayinezinhlangothi ezimbili futhi yanwetshwa eduze nokusanhlamvu, bheka uMdwebo 4 (c), (d). Imvelo kanye nesimo sokucindezeleka kwalawa ma-microcracks acishe afane nalawo e-crack eyinhloko, ngakho-ke kungacatshangwa ukuthi ifomu lokusabalalisa le-crack eliyinhloko liphinde libe yi-intergranular, elibuye liqinisekiswe ngokubhekwa kokuphuka kwe-valve B. I-bifurcation phenomenon ye-crack iphinde ibonise izici zokuqhekeka kokugqwala kwe-valve.

2. Ukuhlaziya kanye Nezingxoxo

Ukufingqa, kungachazwa ukuthi umonakalo we-valve ubangelwa ukuqhekeka kokugqwala kokucindezeleka okubangelwa yi-SO2. Ukuqhekeka kokugqwala kwengcindezi ngokuvamile kudinga ukuhlangabezana nezimo ezintathu: (1) izinto ezizwelayo lapho ukugqwala kwengcindezi; (2) indawo ebolayo ezwela kuma-alloys ethusi; (3) izimo ezithile zokucindezeleka.

Ngokuvamile kunenkolelo yokuthi izinsimbi ezihlanzekile azikhathazwa ukugqwala kwengcindezi, futhi wonke ama-alloys asengozini yokugqwala ngokucindezela ngamazinga ahlukahlukene. Okwezinto zethusi, ngokuvamile kukholakala ukuthi ukwakheka kwesigaba esikabili kunokuthambekela kokugqwala kwengcindezi ephakeme kunesakhiwo sesigaba esisodwa. Kubikwe emibhalweni ukuthi lapho okuqukethwe kwe-Zn kumpahla yethusi kudlula ama-20%, kuba nokuzwela okuphezulu kokugqwala kwengcindezi, futhi ukuphakama kwe-Zn, kuyanda ukuzwela kokugqwala kwengcindezi. Isakhiwo se-metallographic somlomo wegesi kulesi simo siyingxubevange ye-α+β yesigaba esikabili, futhi okuqukethwe kwe-Zn cishe ku-35%, kudlula kude u-20%, ngakho inokuzwela kokugqwala kwengcindezi ephezulu futhi ihlangabezana nezimo zezinto ezibonakalayo ezidingekayo ekuqhekekeni kokugqwala kwengcindezi.

Okwezinto zethusi, uma i-annealing yokunciphisa ingcindezi ingenziwanga ngemva kokuguquka kokusebenza okubandayo, ukugqwala kwengcindezi kuzokwenzeka ngaphansi kwezimo ezifanele zokucindezeleka kanye nezindawo ezigqwalile. Ingcindezi edala ukugqwala kwengcindezi imvamisa ingcindezi yendawo, engasetshenziswa ingcindezi noma ingcindezi eyinsalela. Ngemuva kokuthi isondo leloli selivuthelwe umoya, kuzokwenziwa ingcindezi yokuqina ngokuhambisana ne-axial yenozzle yomoya ngenxa yokucindezela okukhulu kwesondo, okuzodala imifantu ejikelezayo kubhobho lomoya. Ukucindezeleka okuqinile okubangelwa ukucindezela kwangaphakathi kwesondo kungamane kubalwe ngokusho kuka-σ=p R/2t (lapho u-p ewukucindezela kwangaphakathi kwesondo, u-R ububanzi bangaphakathi be-valve, futhi u-t ukuqina kodonga lwe-valve). Kodwa-ke, ngokuvamile, ukucindezeleka okuqinile okukhiqizwa ukucindezela kwangaphakathi kwesondo akukukhulu kakhulu, futhi umphumela wokucindezeleka okusala kufanele ucatshangelwe. Izikhundla zokuqhekeka zemibhobho yegesi zonke zingemuva, futhi kusobala ukuthi ukuguqulwa okusalayo ku-backbend kukhulu, futhi kukhona ukucindezeleka okusalayo lapho. Eqinisweni, ezingxenyeni eziningi ze-copper alloy ezisebenzayo, ukuqhekeka kwe-corrosion ye-stress akuvamile ukubangelwa ukucindezeleka kokuklama, futhi iningi lazo libangelwa ukucindezeleka okuyinsalela okungabonakali futhi kunganakwa. Kulesi simo, ngemuva kokugoba kwe-valve, isiqondiso sokucindezeleka okuqinile okukhiqizwa ukucindezela kwangaphakathi kwesondo kuhambisana nokuqondisa kokucindezeleka okusele, futhi ukuphakama kwalezi zingcindezi ezimbili kunikeza isimo sokucindezeleka se-SCC.

3. Isiphetho kanye Neziphakamiso

Isiphetho:

Ukuqhekeka kwei-valve yesondokubangelwa ikakhulukazi ukuqhekeka kwe-stress corrosion okubangelwa i-SO2.

Ukusikisela

(1) Landela umkhondo wendawo edlayo endaweni ezungezilei-valve yesondo, bese uzama ukugwema ukuthintana ngokuqondile nendawo ezungezile elimazayo. Isibonelo, ungqimba lwe-anti-corrosion coating lungasetshenziswa ebusweni be-valve.

(2) Ukucindezeleka okusalayo kokuqina kokusebenza okubandayo kungaqedwa ngezinqubo ezifanele, njengokunqamula ingcindezi ngemva kokugoba.

Isikhathi sokuthumela: Sep-23-2022