1. Ubunzima benqubo yokuhlanganisa i-Valve Core

Kulolu cwaningo, ngemva kokumunca isipiliyoni sokuklama kwezinye izinhlelo zokuhlanganisa ezizenzakalelayo, kwahlaziywa uhlelo olukhona lwe-semi-automatic, futhi ingxenye yomshini yesistimu yaklanywa ngokuphelele ngokusekelwe ekulingisenii-valve coreinqubo yokuhlanganisa. Ohlelweni lokuklama isistimu, silwela ukwenza ukucutshungulwa kwezingxenye zemishini kube lula, sinciphise izindleko, senze ukuhlangana kwezingxenye kube lula futhi kube lula, futhi senze uhlelo lube nezinga elithile lokuvuleka nokwanda, ukuze kuthuthukiswe ukwethembeka nokusebenza kahle kohlelo. , futhi ubeke isisekelo esihle sokuthuthukisa ukusebenza kwezindleko zesistimu .

Ii-valveumnyombouhlelo lokuhlanganisa luhlukaniswe ngokuyinhloko lube izingxenye ezintathu ngokohlelo lwalo lwesakhiwo semishini, okungukuthi: izingxenye ezimbili zomhlangano ekhoneni eliphezulu kwesokunxele lebhentshi lokusebenzela, izingxenye ezintathu zomhlangano ekhoneni elingezansi kwesokunxele kanye nezingxenye zomhlangano eziyisikhombisa ngakwesokudla kwengxenye yebhentshi lokusebenzela. Ubunzima bezobuchwepheshe bomhlangano wezingcezu ezimbili bulele endleleni yokuqinisekisa ukuma okuyisiyingi kwendandatho yokuvala. Phakathi nenqubo yokusika, izobe ingaphansi kwe-axial extrusion force ye-blade, ngakho-ke kulula ukuguqula. Okwesibili, phakathi nenqubo yokuhlanganisa, lapho kutholwa induku ene-cored engxenyeni yamathuluzi okudlulisa, kuyadingeka ukuqaphela ukuhlonza nokuhlanganisa phakathi kwezingxenye ezihlukene zomgogodla womnyango ngokusebenzisa ukudlidliza. Ngakho-ke, ingxenye ngayinye iwela endaweni ehambisanayo ukuze ibe isixhumanisi somhlangano. Ubunzima benqubo bukhona. Izinkinga ezingenhla ziyizizathu eziyinhloko zokwenyuka kwezinga lomkhiqizo onesici ekuhlanganisweni kwe-valve core kulesi sigaba. Ngokusekelwe kulokhu, leli phepha lithuthukisa inqubo yokuhlanganisa i-valve core, futhi lengeza uhlelo lokuhlola ikhwalithi ukuze kuthuthukiswe izinga lokufaneleka lokuhlanganisa i-valve core.

2. I-Intelligent Valve Core Assembly Scheme

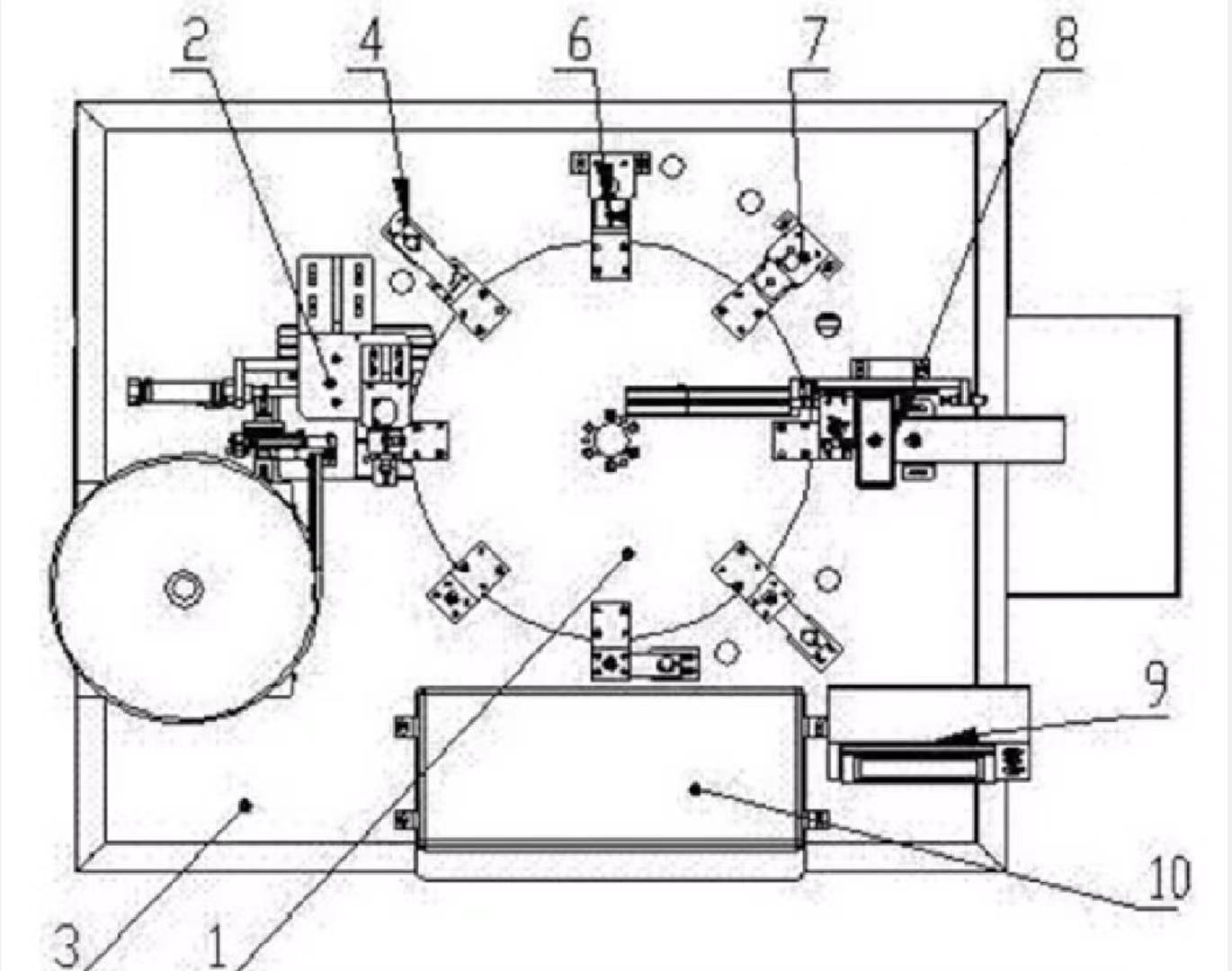

I-interface yokusebenza kanye ne-PLC yakha ingxenye yokulawula okunengqondo, futhi isistimu yokuthola kanye ne-PLC inokugeleza kolwazi lwezindlela ezimbili ukuze kuqoqwe idatha yesimo sesistimu yokuhlanganisa nokukhipha isignali yokulawula. Njengengxenye ephezulu, isistimu yokushayela ilawulwa ngokuqondile ingxenye ye-PLC yokukhipha. Ngaphandle kwesistimu yokudla, edinga usizo lwezandla, ezinye izinqubo kulolu hlelo ziye zaqaphela ukuhlangana okuhlakaniphile. Ukusebenzisana okuhle kwekhompyutha yomuntu kutholakala ngesikrini esithintwayo. Uma kucatshangelwa ukunethezeka kokusebenza ekwakhiweni komshini, ibhokisi lokubeka umgogodla womnyango liseduze nesikrini sokuthinta. Indlela yokubona, ingxenye yomnyango ovuthela phezulu ovula phezulu, ingxenye yokutholwa kokuphakama kwe-valve kanye nendlela evalekile kuhlelwa ngokulandelana kwengxenye yamathuluzi e-turntable, kuqaphela ukuhlelwa kokukhiqizwa komugqa wokuhlanganisa wokuhlanganisa umgogodla womnyango. Isistimu yokuthola ngokuyinhloko iqedela ukutholwa kwenduku ewumgogodla, ukutholwa kobude bokufakwa, ukuhlolwa kwekhwalithi, njll., engaqapheli kuphela ukuzenzekelayo kokukhethwa kwempahla nokukhiya i-valve, kodwa futhi iqinisekisa ukuzinza nokusebenza kahle okuphezulu kwenqubo yokuhlanganisa. Ukwakheka kweyunithi ngayinye yesistimu kuboniswe kuMfanekiso 1.

Njengoba kuboniswe emfanekisweni ongezansi, i-turntable iyisixhumanisi esimaphakathi sayo yonke inqubo, futhi umhlangano we-valve core ugcwaliswa yi-drive ye-turntable. Lapho indlela yesibili yokuthola ithola ingxenye okufanele iqoqwe, ithumela isignali ohlelweni lokulawula, futhi uhlelo lokulawula luhlanganisa umsebenzi weyunithi ngayinye yenqubo. Okokuqala, idiski elidlidlizayo linyakazisa umgogodla womnyango bese liwukhiyela emlonyeni wevalvu yokungena. Indlela yokuqala yokuthola izohlola ngokuqondile ama-valve cores angazange afakwe ngempumelelo njengezinto ezimbi. Ingxenye yesi-6 ithola ukuthi umoya we-valve core ufanelekile yini, futhi ingxenye yesi-7 ithola ukuthi ubude bokufakwa kwe-valve core kuyahlangabezana yini nezinga. Imikhiqizo efanelekile kuphela kulezi zixhumanisi ezintathu ezingenhla izofakwa ebhokisini lomkhiqizo elihle, ngaphandle kwalokho izothathwa njengemikhiqizo enesici.

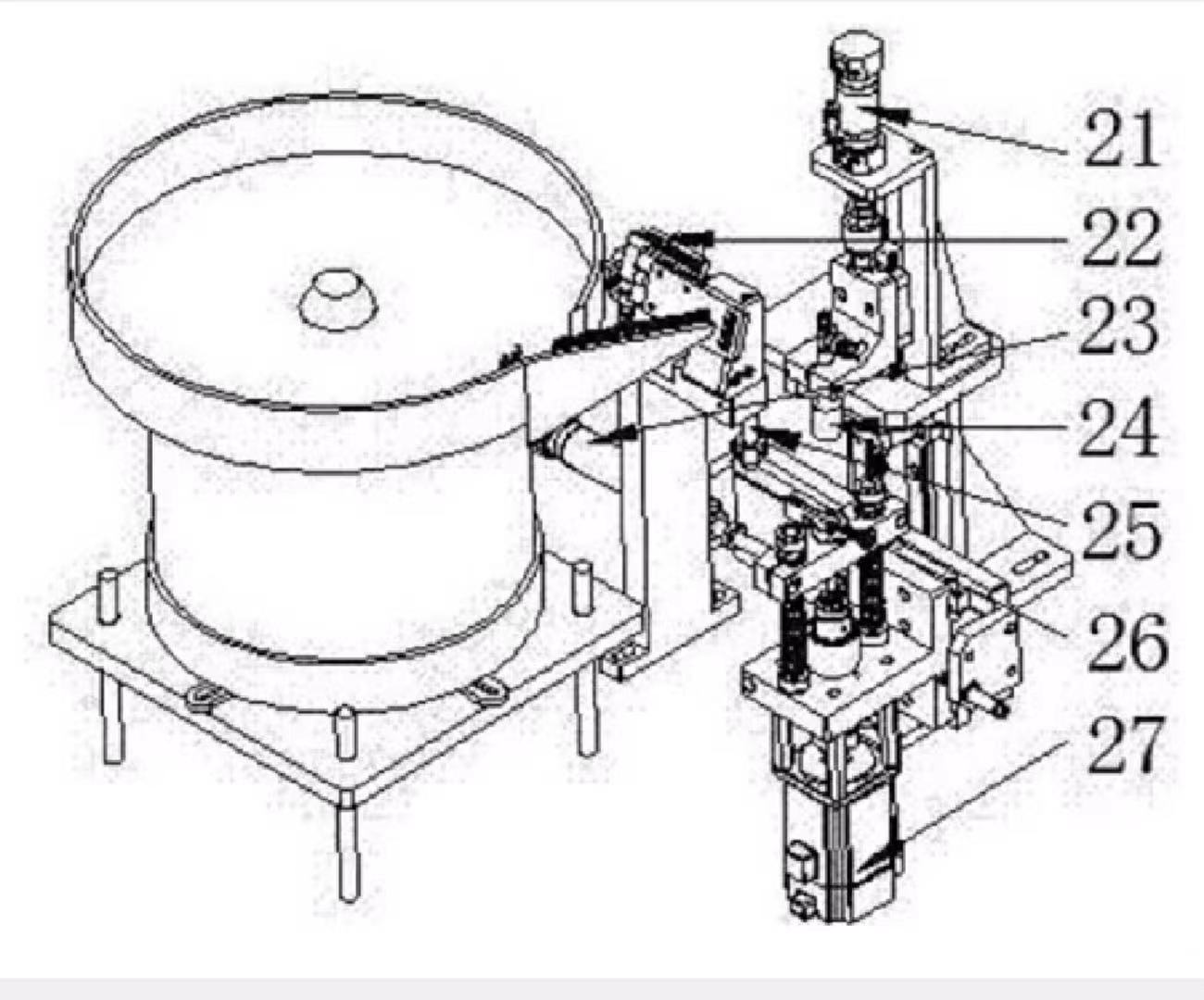

Umhlangano ohlakaniphile wei-valve coreubunzima bezobuchwepheshe bomklamo wesistimu. Kulo mklamo, kwamukelwa umklamo wama-cylinder amathathu. Isilinda sesilayidi silawula ukukhishwa ukuze kuqinisekiswe ukuhluka kokukhishwa; isilinda sesibili siqinisekisa ukuthi induku yokukhiya ihambisana nembobo yokukhipha, bese ibambisana nesilinda se-slide ukuze kuqedelwe umgogodla we-valve ongena endongeni yokukhiya, bese I-cylinder yesibili iqhubeka nokuphusha yonke indlela yokukhiya ukuze inyakaze, futhi umlomo wombhobho wokumunca uzomunca i-valve lapho ifika phansi endaweni yokukhiya. Ekugcineni, ngemva kokuba isilinda sesithathu siphushela indlela yokukhiya endaweni, injini ye-servo ithumela umongo wevalvu emlonyeni wevalvu yokudonsa ukuze iqedele ukuhlanganisa umgogodla wevalvu. Le nqubo iqinisekisa ukunemba nokuhluka kwezikhundla zokunyakaza kwe-longitudinal kanye ne-lateral, futhi inikeza isisombululo esihle sobunzima bezobuchwepheshe bomhlangano oyinhloko womnyango..

3. Ukuklanywa Kwezingxenye Ezibalulekile Zohlelo Lomhlangano We-Valve Core

Njengenqubo eyinhloko yokufaka i-i-valve coreku-valve, ukukhiya umgogodla we-valve kunezidingo eziphakeme kakhulu ekunembeni kokuma kokunyakaza kwe-valve core, ngakho-ke kudinga ukuhlanganiswa kwezinqubo ze-longitudinal kanye ne-lateral ukuze kuqedwe. Ekuklanyweni kwale ngxenye, ichithwa ibe yisenzo esisodwa, isenzo sokukhipha i-valve core, isenzo sokukhiya se-lever yokukhiya kanye nesenzo sokulayisha i-valve core ku-valve nozzle. Isakhiwo sayo semishini siboniswa kuMfanekiso 2. Njengoba kungabonakala kuMfanekiso 2, ukwakheka komshini womhlangano we-valve core kuhlukaniswe izingxenye ezintathu. Izingxenye ezintathu zisebenza ngokubambisana ngaphandle kokuthintana. Lapho isenzo sokuzimela sesiqediwe, isilinda siphusha indlela yokuthuthela endaweni yokuhlanganisa elandelayo.

Ukuze kuqinisekiswe ukunemba kwesimo esinyakazayo, umklamo obanzi wokulawula ugesi kanye nomkhawulo wemishini uyamukelwa ukulawula iphutha ngaphakathi kwe-1.4mm. I-valve core kanye nendawo ephakathi yenozzle ye-valve i-coaxial, ukuze i-servo motor ikwazi ukusunduza umgogodla we-valve ngokushelela, ngaphandle kwalokho izodala umonakalo ezingxenyeni. Ukuma kwesakhiwo somshini noma ama-pulses angavamile amasignali kagesi kungabangela ukuchezuka okuncane emsebenzini wokuhlanganisa. Ngenxa yalokho, ngemva kokuba i-valve core iqoqwe, ukusebenza kwe-ventilation akufinyeleleki ezingeni elijwayelekile, futhi ukuphakama komhlangano akufanelekile, okuholela ekuhlulekeni komkhiqizo. Lesi sici sicatshangelwa ngokugcwele ekwakhiweni kwesistimu, ukutholwa kokushaywa komoya nokutholwa kobude kusetshenziselwa ukuhlunga imikhiqizo emibi.

Isikhathi sokuthumela: Sep-09-2022