1. Isizinda Sokukhiqiza

Kuwoyela osindayo owengeziwe e-Xiaowa Oilfield, iyunithi yokumpompa esetshenziselwa ukumba izimayini. Ukuze uthole umfutho obheke phezulu, indawo yokumisa ikhanda idinga ukuphakamisa induku kawoyela. Uma umshini wokudonsa wehla ngekholomu, ikholomu ye-liquid ayivunyelwe ukunyuka lapho iphampu idonsa, ukuze isimo sekhanda lembongolo sishintshe. Ku-downstroke, i-locomotive idlala indima ngaphansi kwesenzo sesisindo sayo, idlala indima enqubweni yokusebenza, ivumela ukuthi idlale indima yayo, idlale indima yayo, idlala indima ngaphansi kwesenzo sesisindo somkhumbi, idlala indima ekusebenzeni, futhi Ayidlali indima emathangini, hhayi ibhalansi. Umsebenzi owenziwe ngezandla ohlelweni lokumpompa awuhlukanisi ukungalingani kweyunithi yokupompa.

2. Izingozi Zeyunithi Yokupompa Okungalingani

Lapho i-izisindo zamasondoayilingani, izoletha izingozi ezilandelayo:

(1) Yehlisa ukusebenza kahle nempilo yemoto. Ngenxa yomthwalo ongalingani, i-motor kagesi ithwala umthwalo omkhulu ku-stroke yaphezulu, futhi iyunithi yokumpompa igijima ne-motor kagesi ku-stroke ephansi, okuholela ekumosheni kwamandla nokunciphisa ukusebenza kahle nokuphila kwe-motor kagesi.

(2) Nciphisa impilo yesevisi yeyunithi yokumpompa. Ngenxa yomthwalo ongalingani, umthwalo uba mkhulu ngokuzumayo futhi ube mncane phakathi nokuphenduka okukodwa kwe-crank, okuzobangela iyunithi yokumpompa ukuthi idlidlize ngamandla futhi ifinyeze impilo yeyunithi yokumpompa.

(3) Kuthinta ukusebenza okuvamile kweyunithi yokumpompa kanye nepompo. Ngenxa yomthwalo ongalingani, ukufana kwejubane lokujikeleza kwe-crank kuzobhujiswa, ukuze ikhanda lembongolo lingashwibi ngokulinganayo liye phezulu naphansi, okuzothinta ukusebenza okuvamile kweyunithi yokupompa kanye nepompo.

Ngenxa yalesi sizathu, ngenxa yezinkinga ezibangelwa ukungalingani kweyunithi yokupompa, ukulungiswa nokulinganisela kweyunithi yokupompa sekube umsebenzi ovame kakhulu emsebenzini wokukhiqiza nsuku zonke wendawo yokusebenza yokukhiqiza uwoyela. Umthombo ngamunye kawoyela udinga ukulungiswa futhi ulinganisele kanye noma kabili ngonyaka. Ngokwezibalo, ngo-2015, isilinganiso senani lokulungiswa kokulinganisa ngenyanga endaweni yokusebenza sifinyelele izikhathi ezingu-15 kuya kwezingu-20. Ngokwesimo samanje sokulungiswa kokulinganisa, kudinga isikhathi eside sokuvala, esinomthelela omkhulu emithonjeni yamafutha esindayo, okulula ukubangela ukwehla kwe-liquid nokuphuma. , imithombo ebambekile, njll. Ngakho-ke, kuyaphuthuma ukuthuthukisa idivayisi enganciphisa isikhathi sokulinganisa iyunithi yokupompa.

3. Isixazululo

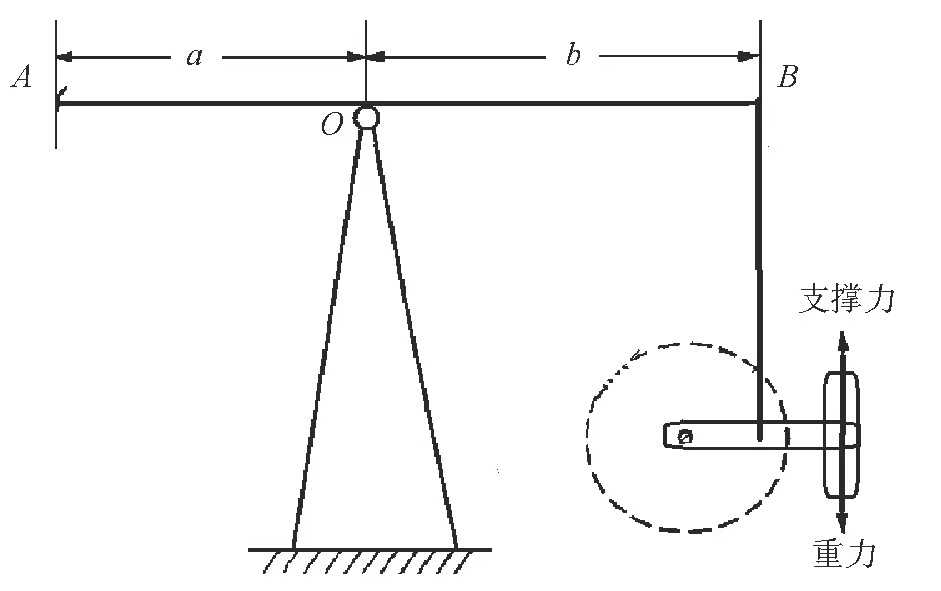

Njengamanje, ukulungisa isisindo sebhalansi yeyunithi yokumpompa ukulungisa i-crank iye endaweni evundlile ngebhuleki, futhi usebenzise ithuluzi ukuhambisa isisindo sebhalansi endaweni ebekiwe (Umfanekiso 1). Indawo evundlile ye-crank ikhethwa ngenxa yokuthi isiqondiso esime mpo sesisindo sebhalansi sithinteka kuphela isisindo sebhalansi yesisindo namandla asekelayo e-crank esisindweni sebhalansi. Awekho amandla endaweni evundlile, futhi isesimweni esimile. Ngalesi sikhathi, amandla angaphandle asetshenziselwa ukusunduza ibhalansi endaweni eqokiwe, okuyiyona eyonga kakhulu umsebenzi.

Uma kucatshangelwa indawo ye-crank yeyunithi yokumpompa, indawo evundlile kuphela nendawo engemuva engakhethwa ukuze kulungiswe indawo yokusebenza yesisindo sebhalansi. Ngemva kokuhlaziya okuqhathanisayo (Ithebula 2), kunqunywa ukuthi idivayisi esebenzayo ithatha indawo evundlile. Ngemuva kokuthi indawo yokulungisa inqunywa njengendiza ye-crank, indlela yokulungisa iyahlaziywa. Ngokuqonda izindlela zokulungisa emakethe kanye nesimo sangempela se-crank, kuyaziwa ukuthi indlela yokulungisa yeselula ingakhetha kuphela uxhumano olunentambo kanye noxhumo lwe-clamp. Ngemva kophenyo nezingxoxo, izinzuzo kanye nebubi bendlela engaguquki kwaqhathaniswa futhi kwahlaziywa (Ithebula 4). Ngemuva kokuthi ukuqhathanisa nokuhlaziywa kwezinhlelo sekuqediwe, indlela yokugcina yokulungisa ikhethwa njengoxhumano lwentambo. Ngemva kokukhetha indawo yokusebenza yedivayisi yeselula njengendawo evundlile, nokukhetha indawo egxilile njengendiza ye-crank, kubalulekile ukukhetha indawo yokuxhumana phakathi kwedivayisi yeselula nesisindo sebhalansi. Ngenxa yezici ze-balance block ngokwayo, uhlangothi lwe-balance block luyindawo yokuxhumana, futhi idivayisi yeselula ingaba ku-point-to-surface, ukuxhumana okungaphezulu kuya kobuso.

4. Ukuhlanganiswa Kwezingxenye

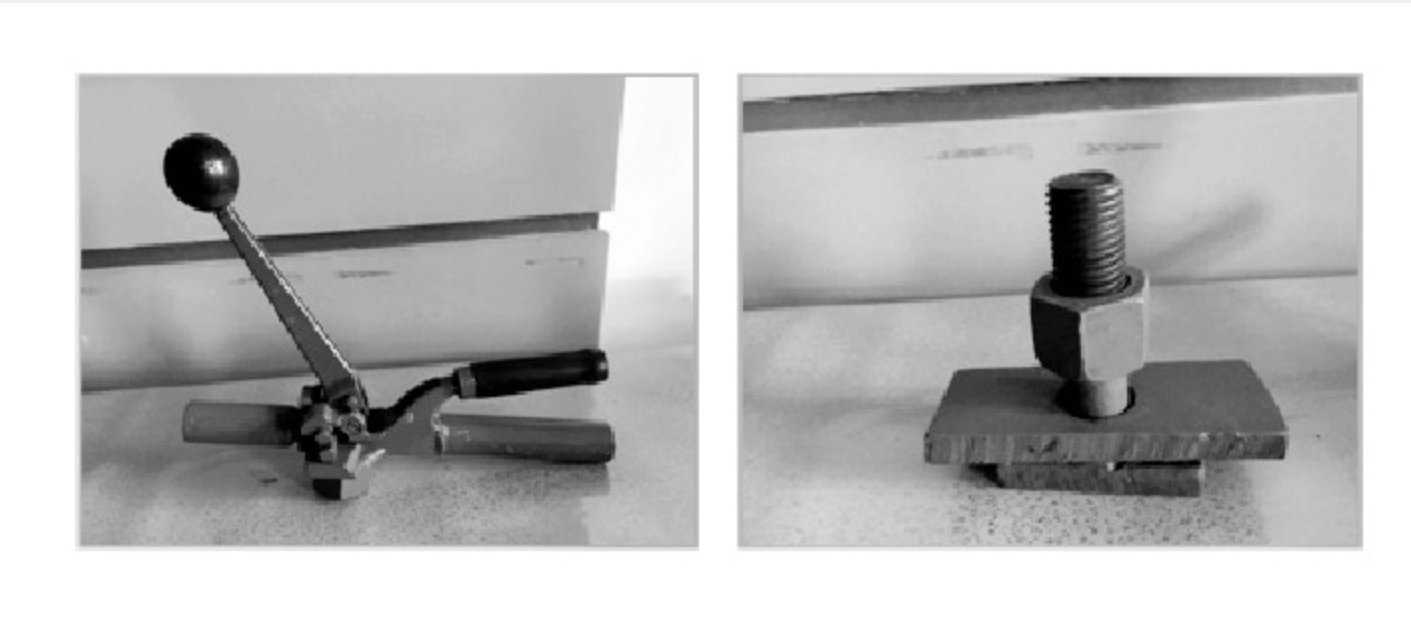

Izingxenye zedivayisi yeselula kanye nemiphumela yazo yokuhlanganisa kuboniswa esithombeni esingezansi.

Iizinsimbi zokunamathisela, ukunyakaza okuphindaphindiwe kokuya phezulu naphansi kuguqulwa kube ukujikeleza okuphambene newashi kwegiya lokudlulisela, futhi umkhawulo wephini lokukhiya izinyo eliyinhloko, ukushayela ibhande lezinyo ukuze linwebe, ukuze kufezwe injongo "yokukhulisa nokuqinisa" (Umfanekiso 3). NgoSepthemba 2016, ukuhlolwa kokusebenza kokulungiswa kwebhalansi kwenziwa ku-Well 2115C kanye ne-Well 2419 yase-Wa Shiba Station. Ukuhlolwa kokufakwa kokulungisa indawo yebhalansi yebhalansi kule mithombo emibili kuthathe imizuzu emi-2 nemizuzu engu-2.5 ngokulandelana (Ithebula 9).

Kungabonakala emphumeleni wokufaka wemithombo emibili (Fig. 4) ukuthi idivayisi ihlangabezana ngokugcwele nezidingo zokukhiqiza kusayithi, futhi ukulungiswa nokusebenza kwebhalansi kuyaguquguquka futhi kuyashesha, ukonga isikhathi nomzamo. Indawo yokusebenza idinga ekuphathweni kokukhiqiza: ngenxa yezinguquko ezinkulu emingceleni yokukhiqiza yomthombo wamafutha esindayo, iyunithi yokupompa kufanele ilungiswe futhi ilinganise ngesikhathi ngokusho kwezinguquko zomthwalo kanye namanje. Ukufakwa kwedivayisi kusiza nokusebenza kwabasebenzi futhi kunciphisa umfutho wabasebenzi. I-portable oil pumping unit balance weight idivayisi yeselula iphephile futhi inokwethenjelwa ukuyisebenzisa, kulula ukuyisebenzisa, isayizi encane, ilula ngesisindo, ilungele ukuthwala, inezinhlobonhlobo zezinhlelo zokusebenza, futhi inezindleko eziphansi zokukhiqiza.

Ngemuva kokuthi ukuhlolwa kube yimpumelelo, ithimba lenze ukukhuthazwa nokufaka isicelo eqenjini lesishiyagalombili lokukhiqiza uwoyela. Kusukela ngoSepthemba kuya ku-Okthoba 2016, ukusebenza kokulungiswa kwebhalansi kwenziwa emithonjeni emi-5, okuthathe isilinganiso semizuzu engama-21.5, futhi kwafeza umphumela olindelekile nofanelekile.

5. Isiphetho

(1) Lolu cingo lunciphisa umfutho wokusebenza kwabasebenzi futhi luthuthukise isici sokuphepha sokusebenza komthombo.

(2) Qinisa ukunakekelwa kweyunithi yokumpompa, thola izingozi ezifihliwe futhi uqede izinto ezingavamile ngesikhathi, ukuze iyunithi yokumpompa isebenze ngaphansi kwezimo ezingcono kakhulu zokusebenza.

(3) Idivayisi inezinzuzo zokuklama okuphusile, ukwakhiwa okulula, ukusebenza okuthembekile, ukusebenza esizeni esikahle, ukutshalwa kwezimali okuphansi nokuphepha okuphezulu, futhi ifanele ukukhuthazwa nokusetshenziswa okuqhubekayo.

Isikhathi sokuthumela: Oct-13-2022