1. Ulwazi Olungemuva

I-Double Mass Fly Wheel (DMFW) ukulungiselelwa okusha okuvele ezimotweni ngasekupheleni kwawo-1980, futhi kunomthelela omuhle ekuhlukaniseni ukudlidliza kanye nokwehliswa kokudlidliza kwezitimela zamandla emoto.

Iamantongomaneiwukuhlukanisa i-flywheel yasekuqaleni ibe izingxenye ezimbili. Ingxenye eyodwa ihlala ohlangothini olulodwa lwenjini yokuqala futhi isebenza njenge-flywheel yokuqala futhi idlulise i-torque ejikelezayo yenjini. Le ngxenye ibizwa ngokuthi i-primary mass; enye ingxenye ibekwe ohlangothini lokudlulisela lwe-driveline ukuze kuthuthukiswe inertia ejikelezayo yokudlulisela. , le ngxenye ibizwa ngokuthi i-secondary mass. Kukhona i-annular oil cavity phakathi kwezingxenye ezimbili, futhi i-spring shock absorber ifakwe emgodini, obhekene nokuxhuma izingxenye ezimbili ze-flywheel, njengoba kuboniswe ku-Figure 1. Isisindo sesibili singandisa umzuzu we-inertia wesitimela sokushayela ngaphandle kokwandisa umzuzu we-inertia we-flywheel, futhi unciphise isivinini se-resonance ngaphansi kwejubane elingenalutho.

Ifekthri ye-Hexi base injini ikhiqiza izinjini ze-dual-mass flywheel ezingu-5, okuyi-EK/CM/RY/SN/TB. Amasondo ama-dual-mass flywheels alezi zinjini ezi-5 aqiniswa yisiteshi esizishintshayo (OP2135), kanti amabhawodi okuqinisa ama-flywheel ama-dual-mass amabhawodi e-Torx. Ukunemba kokuqinisa kuyadingeka ukuze kube phezulu, futhi ukuchezuka kancane ku-engeli kuzobangela ukuthi ukuqinisa kungalungile ku-shaft. Ngokwesilinganiso, kuvele imikhiqizo engu-15 engafanelekile ekushintsheni ngakunye, okubangele inani elikhulu lokulungiswa futhi kuthinte ukusebenza okuvamile komugqa wokukhiqiza.

Okwamanje, isiteshi sokuqinisa amasondo okundiza okuphindwe kabili sisebenzisa indlela yokulawula ye-torque plus angle (35±2)N m+(30~45)° ukuze kuqashwe itorque yebhawodi. Ngaphezu kwalokho, i-torque emile yebhawodi ye-dual-mass flywheel inkulu (izidingo zobuchwepheshe: 65 N·m ~ 86 N·m). Ukuze kuhlangatshezwane nezidingo ze-torque, kuyadingeka ukuthi umkhono (njengoba kuboniswe kuMfanekiso 3) kanye nebhawodi kufanele kuhambisane ngokunembe kakhulu phakathi nenqubo yokuqinisa. Ngenxa yalesi sizathu, leli phepha lenza uphenyo kanye nokuhlaziya okusekelwe ezimweni zezinkinga zangempela, futhi liphakamisa izixazululo ezifanele zendlela yokuthuthukisa izinga elifanelekayo lokuqiniswa kwebhawodi le-flywheel eliphindwe kabili.

2. Uphenyo Lokuqiniswa Okungafanele Kwamantongomane

Inkinga "yokuqinisa ngokungalungile ku-I-Lug Nuts" ibalwa ku-94.63% yenani eliphelele labangaqeqeshiwe, okwakuyinkinga enkulu ebangela izinga eliphansi elifanelekayo lokuqiniswa kwe-double-mass flywheel bolt. Ngemva kokunquma i-crux yenkinga eyinhloko, singakwazi ukunikeza umuthi ofanele. Kuhlanganiswe nendawo yesehlakalo kanye nesimo sokukhiqiza, isiqondiso esiyinhloko socwaningo siye sacaciswa.

Ngokusho kwedatha yophenyo lwesimo samanje, idatha yamabhawodi e-dual-mass flywheel angu-459 kusukela ngoJanuwari kuya ku-March 2021 ayizange iqiniswe futhi idatha ye-shaft yahlaziywa, njengoba kubonisiwe kuThebula 1 kanye noMfanekiso 6. Ngemva kokuhlaziywa, kwatholakala ukuthi angu-25 amabhawodi e-dual-mass flywheel ahlulekile ukuqiniswa ngenxa yokungacaciswanga kwemishini yekhamera. ukusebenza okungalungile kwe-pallet, ukulahlekelwa umsuka wemishini, ukulimala komkhono, njll., kunokungahleliwe okukhulu. Ngakho-ke, i-crux eyinhloko yale nkinga ingaxazululwa ngokwethiyori ngezinga elingu-1-25/459=94.83%.

3. Isixazululo

1. Isixazululo sokugqokwa kwamazinyo okusebenza emihlathini ye-flywheel

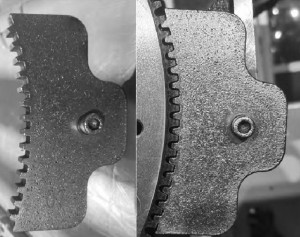

Ibheka uzipho lwe-flywheel olusendaweni, kwatholakala ukuthi amazinyo e-flywheel claw tooling ayeguge kakhulu, futhi amazinyo awakwazanga ukuhlanganisa igiya leringi ye-flywheel. Phakathi nenqubo yokuqinisa imishini, i-flywheel iyazamazama, okwenza umkhono ungaqondani kahle nebhawudi. Phakathi nenqubo yokuqinisa, umkhono ugxuma uphume ebhowudeni, noma ujikeleze ngokungenzi lutho phezu kwebhawodi, okuholela ekuqinisweni okungafanelekile.

Buyisela ithuluzi elisha lozipho lwe-flywheel, usuku lokusetshenziswa luphawulwe ku-claw tooling, futhi okokusebenza kufanele kushintshwe njalo ngemva kwezinyanga ezi-3 ukuze kugwenywe ukuzamazama kwe-flywheel phakathi nenqubo yokuqinisa ngenxa yokuguga kwe-claw, okuzobangela ukuthi i-shaft engafanelekile yenzeke.

2. Isixazululo sokukhulula i-bayonet yethreyi

Hlola amarekhodi okusebenza kabusha kwephalethi akusayithi. Amaphalethi enjini asetshenziwe kabusha avame ukugxila ku-021#/038#/068#/201#. Khona-ke ama-pallets ahlolwe futhi athola ukuthi izikhonkwane zokulungisa i-pallet zazikhululekile. Ngenxa yalokho, umkhono awuqondani nebhawodi, umkhono ugxumela ngaphandle kwebhawodi phakathi nenqubo yokuqinisa, noma ukungenzi lutho ebusweni bebhawodi kubangela ukuqina okungafanelekile. Uma ama-bolts okulungisa e-bayonet ye-pallet ekhululiwe, i-bayonet ayikwazi ukulungiswa ngokuphumelelayo. Ukuze uthole ibhulokhi yokulungisa ye-pallet, sebenzisa amabhawodi anwetshiwe (amabhawodi amafushane ngaphambili), futhi usebenzise amantongomane anqanda ukuhlehla ukuze uwalungise ukuze ugweme i-bayonet ye-bayonet okubangelwa ukuxegiswa kwe-pallet bayonet fixing bolts. Ngeke ilungiswe ngokuphumelelayo, okuholela ekunyakazeni kwe-flywheel futhi imise kabi i-shaft ngesikhathi senqubo yokuqinisa, engafaneleki.

3. Lungiselela indlela yokuthatha izithombe zekhamera yocingo

Lesi sinyathelo siyingxenye enzima kakhulu yohlelo. Ngenxa yokuthi awekho amapharamitha okubhekiselwa kuwo, kuyadingeka ukuhlola nokulawula okokusebenza. Uhlelo oluthile:

(1) Lungisa kabusha izixhumanisi zomsuka

(2) Khulisa uhlelo lwepharamitha yesinxephezelo sesikhungo sesithombe sekhamera, njengengxenye yesithombe esimaphakathi nembobo, setha inani lesinxephezelo kanye nenani lokulungisa lezixhumanisi ezimaphakathi, futhi ulungise indawo ephakathi nendawo yembobo.

(3) Lungisa inani lesinxephezelo sokuchayeka kwekhamera.

Idatha yalandelelwa ngokuqhubekayo futhi yaqoqwa izinyanga ezi-3. Ngalesi sikhathi, izinga elifanelekile lokuqiniswa kwebhawudo ye-flywheel yesisindo esiphindwe kabili liye laguquguquka, futhi kwalungiswa nokulungiswa okufanele kumapharamitha wokuthwebula izithombe. Ekuqaleni kuka-April, inani lesinxephezelo sokuchayeka lashintshwa lisuka ku-2 800 laya ku-2 000, futhi izinga lokuqina lokufundela lenyuka lafinyelela ku-97.75%. , kube nokuhluleka okwengeziwe ngemva kokusebenza kokulandelela, bese inani lokuvezwa kwekhamera lilungiswa: kusuka ku-2 000 kuya ku-1 800, ekhuphuke yaba ngu-98.12%; ukuze kuqiniswe izinyathelo, phakathi nenqubo yokulandela umkhondo, inani lokuchayeka kwekhamera laphinde lathuthukiswa: lisuka ku-1 800 laba yi-1 000, futhi izinga lokuphasa eliqinisayo lokugcina ngo-April lenyuke laya ku-99.12%; izinga lokuphasa eliqiniswayo ngoMeyi nangoJuni lalandelelwa ngokuqhubekayo lafinyelela ngaphezu kwama-99%.

4. Ukulalela

I amantongomaneI-flywheel iyithuluzi elinomphumela omuhle kakhulu wokuhlukanisa ukudlidliza kanye nomthelela wokunciphisa ukudlidliza emotweni yamanje. Ukudlidliza kwenjini kadizili kukhulu kunokwenjini kaphethiloli. Ukuze kuncishiswe ukudlidliza kwenjini kadizili futhi kuthuthukiswe ukunethezeka kokugibela, izimoto eziningi zikadizili eYurophu manje zisebenzisa amasondo ahamba ngamabili, ukuze ukunethezeka kwemoto enenjini kadizili kuqhathaniswe nokwemoto enenjini kaphethiloli [6]. E-China, i-FAW-Volkswagen's Bora transmission sedan ihambe phambili ekuthatheni amasondo ahamba ngamabili. Isidingo semakethe samasondo omabili anobunzima obubili siyaqhubeka nokukhula, futhi izimfuneko zokuqiniswa kwamazinga emfundo nazo ziya ngokuya zikhuphuka [7]. Lesi sihloko sihlaziya izinkinga ezivamile eziholela ekuqinisweni okungafanelekile kwe-double mass-mass flywheel, ithola umsuka wayo, yenza izindlela zokuxazulula izinkinga, futhi ixazulule inkinga ngokuyisisekelo. Njengamanje, imishini isebenza kahle, futhi izinga lokuphasa lisengaphezu kwama-99%. Isixazululo sale nkinga sinokubaluleka okuhle ekongeni izindleko zabasebenzi kanye nokwenza ngcono ikhwalithi yefekthri.

Isikhathi sokuthumela: Sep-29-2022