1. Kafushane

Intambo yangaphakathi esetshenziswa amagagasi e-longitudinal futhi ekhethiwe ukuthi isetshenziswe ilungiswa nguamabhawodi ajwayelekilenamabhawodi azikhiyayo, alinganiswa ngamasu ahlukene okuqiniswa, futhi umehluko phakathi kwamabhawudo okusetshenzwa kulengwa kuwo kanye namajika esici okubambelela okuzikhiya ayahlaziywa. Umphumela: Indlela yokulinganisa ibhawudi nebhawodi izothola izici zokulinganisa ezihlukene, isikali sesikhathi sokukhiya seketango senza ukuzilinganisa ngokwakho kanye nesilinganiso sesikhathi sokuzilinganisa sokuzilinganisa siholele kokuhlosiwe okuhlukene. Ngenxa yejika elivamile lokunyakaza, izici zesici ezitholiwe ezihlukile zizoya kwesokudla .

2. Ifilosofi Yokuhlola

Njengamanje, indlela ye-ultrasonic isetshenziswa kabanzi ku-i-bolt axial force testindawo yokuqiniswa yesistimu engaphansi yemoto, okungukuthi, ijika lesici sobudlelwano (ijika lokulinganiswa kwebhawudi) phakathi kwamandla e-axial yebhawudo kanye nomehluko wesikhathi somsindo we-ultrasonic utholwa kusengaphambili, futhi ukuhlolwa okulandelayo kwengxenye yangempela yesistimu engaphansi iyenziwa. Amandla e-axial webhawodi ekuxhumekeni okuqinisayo angatholwa ngokulinganisa nge-ultrasonical umehluko wesikhathi somsindo webhawodi futhi ubhekise kwijika lokulinganisa. Ngakho-ke, ukuthola ijika elilungile lokulinganisa kubaluleke kakhulu ekunembeni kwemiphumela yokulinganisa amandla e-axial bolt kusistimu yengxenye yangempela. Njengamanje, izindlela zokuhlola ze-ultrasonic ikakhulukazi zifaka indlela yegagasi elilodwa (okungukuthi indlela yamagagasi e-longitudinal) kanye nendlela yamagagasi e-longitudinal eguquguqukayo.

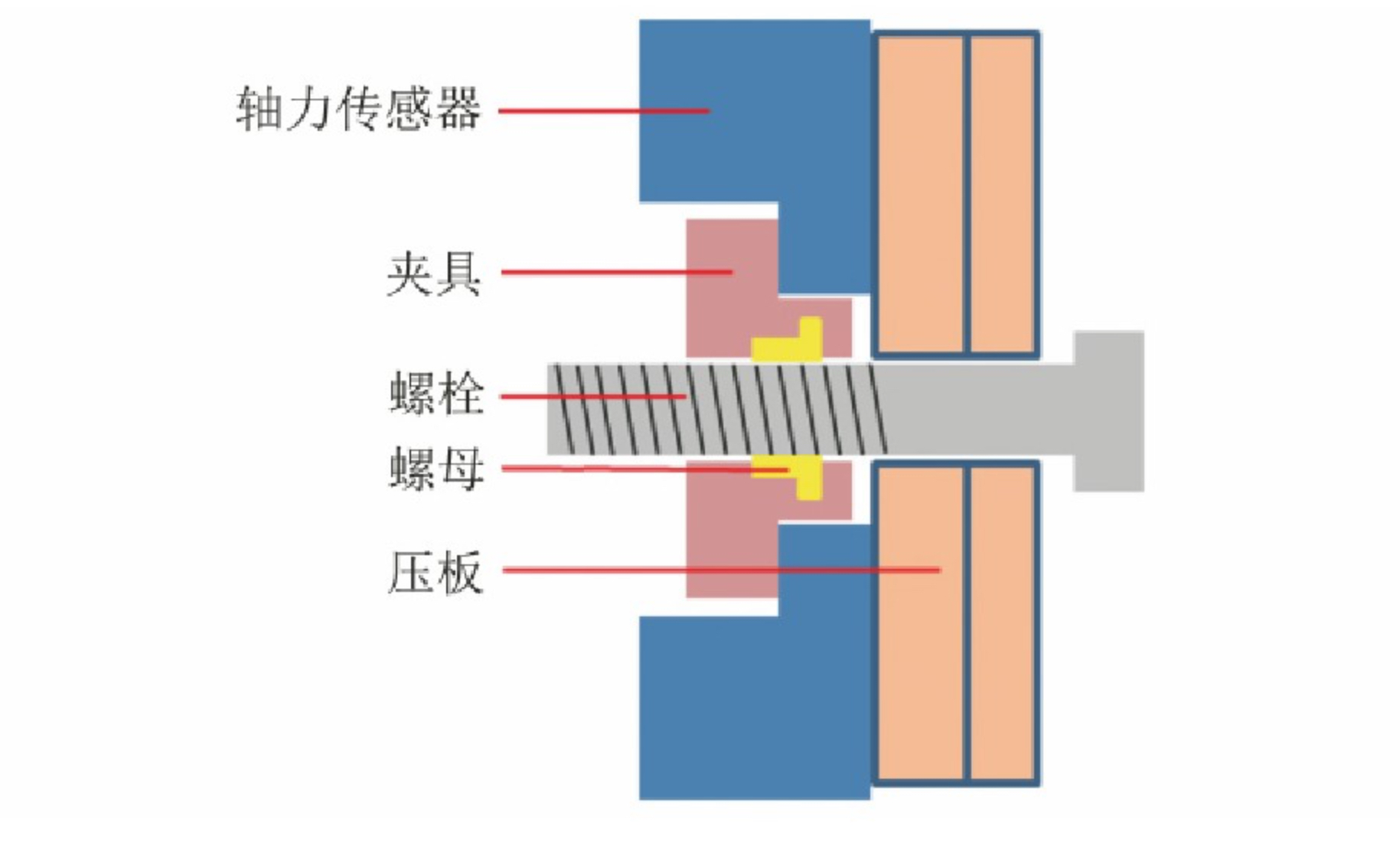

Enqubweni yokulinganiswa kwebhawodi, kunezici eziningi ezithinta imiphumela yokulinganisa, njengobude bokubopha, izinga lokushisa, isivinini somshini oqinisayo, ithuluzi lokulungisa amabhawodi, njll. Okwamanje, indlela yokulinganisa ibholithi evame ukusetshenziswa kakhulu yindlela yokuqinisa ukuzungezisa. Amabhawodi akalwa ebhentshini lokuhlola ibhawudi, elidinga ukukhiqizwa kwezinto ezisekelayo zenzwa yamandla e-axial, okuyipuleti lokucindezela kanye nembobo enentambo yangaphakathi. Umsebenzi wokulungisa imbobo enentambo yangaphakathi Ukubuyisela amantongomane avamile. I-Anti-loose design ivame ukusetshenziswa ezindaweni zokuxhuma eziqinisayo ezinesici sokuphepha esiphezulu se-chassis yezimoto ukuze kuqinisekiswe ukwethembeka kokuqiniswa kwayo. Esinye sezinyathelo zokulwa nokuxega esamukelwe njengamanje inati elizivalayo, okungukuthi, nati elikhiya itorque elisebenzayo .

Umbhali wamukela indlela yegagasi le-longitudinal futhi usebenzisa intambo yangaphakathi eyenziwe mathupha ukuze akhethe inadi elivamile nenathi elizikhiyayo ukuze alinganise ibhawudi. Ngamasu ahlukene okuqinisa nezindlela zokulinganisa, umehluko phakathi kwenadi elivamile nenathi elizikhiyayo ukuze kulinganiswe ijika lebhawodi liyafundwa. Ukuhlolwa kwe-Axial force yezibophelelo zesistimu engaphansi kwezimoto kwenza izincomo ezithile.

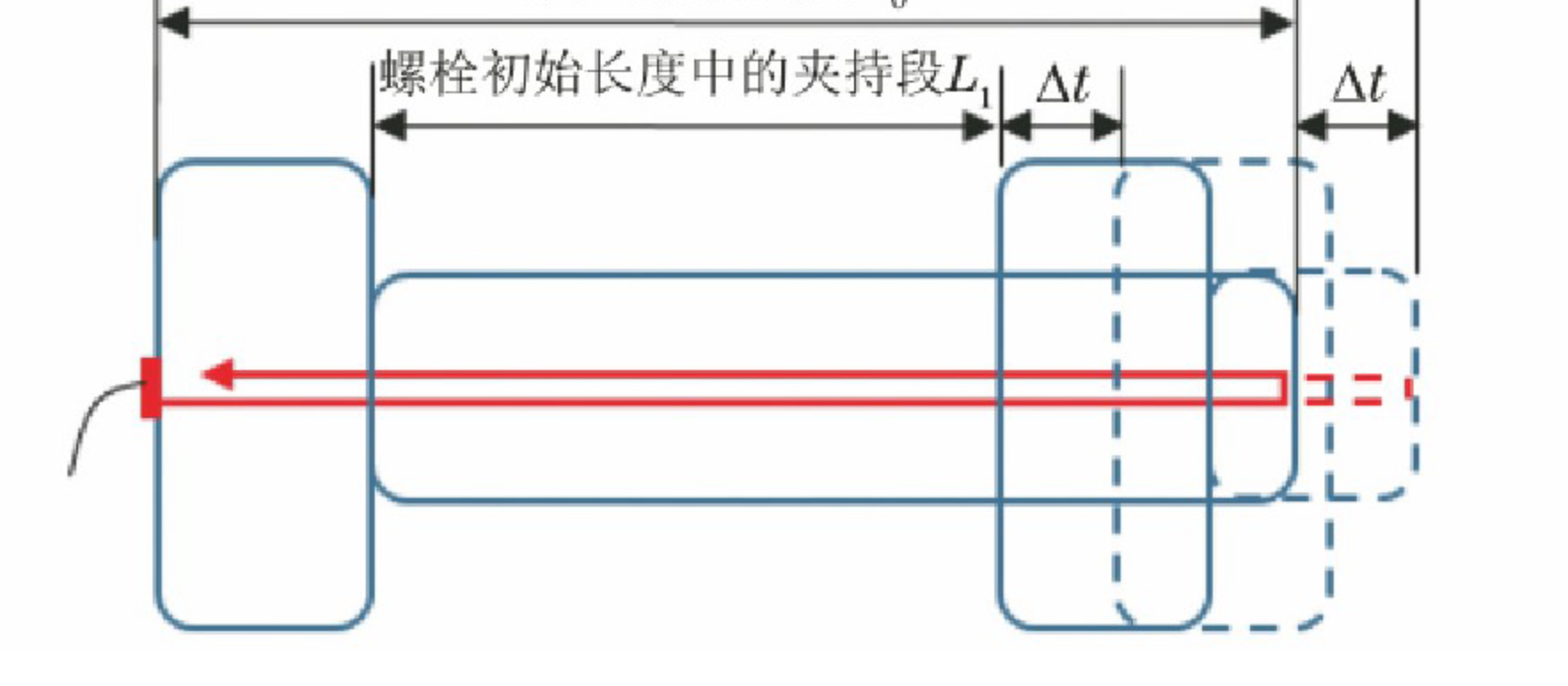

Ukuhlola amandla e-axial amabhawodi ngobuchwepheshe be-ultrasonic kuyindlela yokuhlola engaqondile. Ngokusho kwesimiso se-sonoelasticity, isivinini sokusakazeka komsindo ezintweni eziqinile sihlobene nokucindezeleka, ngakho-ke amagagasi e-ultrasonic angasetshenziswa ukuthola amandla e-axial of bolts [5-8]. I-bolt izozelula ngokwayo ngesikhathi senqubo yokuqinisa, futhi ngesikhathi esifanayo ikhiqize ukucindezeleka kwe-axial tensile. I-pulse ye-ultrasonic izodluliselwa kusuka ekhanda lebhawodi kuya emsileni. Ngenxa yokushintsha okungazelelwe kokuminyana kwe-medium, izobuyela endleleni yokuqala, futhi ingaphezulu lebhawodi lizothola isignali nge-ceramic piezoelectric. umehluko wesikhathi Δt. Umdwebo we-schematic wokuhlolwa kwe-ultrasonic uboniswa kuMfanekiso 1. Umehluko wesikhathi ulingana nobude.

Ukuhlola amandla e-axial amabhawodi ngobuchwepheshe be-ultrasonic kuyindlela yokuhlola engaqondile. Ngokusho kwesimiso se-sonoelasticity, isivinini sokusakazeka komsindo ezintweni eziqinile sihlobene nokucindezeleka, ngakho-ke amagagasi e-ultrasonic angasetshenziswa ukuthola.amandla e-axial amabhawodi. I-bolt izozelula ngokwayo ngesikhathi senqubo yokuqinisa, futhi ngesikhathi esifanayo ikhiqize ukucindezeleka kwe-axial tensile. I-pulse ye-ultrasonic izodluliselwa kusuka ekhanda lebhawodi kuya emsileni. Ngenxa yokushintsha okungazelelwe kokuminyana kwe-medium, izobuyela endleleni yokuqala, futhi ingaphezulu lebhawodi lizothola isignali nge-ceramic piezoelectric. umehluko wesikhathi Δt. Umdwebo we-schematic wokuhlolwa kwe-ultrasonic uboniswa kuMfanekiso 1. Umehluko wesikhathi ulingana nobude.

I-M12 mm × 1.75 mm × 100 mm bese ukucaciswa kwamabhawodi, sebenzisa amabhawodi ajwayelekile ukulungisa amabhawodi ayi-5, qala usebenzise ukuhlolwa okuzibambele mathupha ngezindlela ezahlukene zokunamathisela i-solder yokulinganisa, kuyipuleti elivunguzayo lokufakelwa ukubopha i-flange bese ucindezela Lapho uskena igagasi lokuqala (okungukuthi, ku-0 0 m3), urekhoda igagasi lokuqala (okungukuthi, i-N0 0) bese urekhoda i-wave yokuqala (okungukuthi, i-N0) ngethuluzi elilodwa (elibizwa ngokuthi indlela yohlobo lwe-I), kanti elinye elokuskena igagasi lokuqala bese lisikulufa kusayizi oqondiwe ngesibhamu esiqinisayo (okuthiwa indlela yohlobo I). Ngokwendlela yohlobo lwesibili), kuzoba nohlobo oluthile kule nqubo (njengoba kuboniswe kuMfanekiso 4) 5 iwukuba umshudo ovamile kanye nendlela yokuzikhiya Ijika ngemva kokulinganisa ngokohlobo lwendlela I Umfanekiso 6 wuhlobo lokuzikhiya. Umfanekiso 6 uyikilasi lokuzikhiya. Amajika ekilasi I kanye neClass II. Indlela yokusebenzisa ingaba, sebenzisa ijika langokwezifiso lekilasi le-anchor elivamile, lifane ncamashi (konke kudlula imvelaphi ngesilinganiso sesegimenti esifanayo nenani lamaphuzu); khiya uhlobo lwenkomba yohlobo lwephoyinti lehange (uhlobo I kanye nophawu lwehange, ukuthambeka komehluko wesikhawu kanye nenani lamaphoyinti); thola ukufana)

Ukuhlola 3 ukusetha i-Y3 coordinate of Graph Setup kusofthiwe yethuluzi lokutholwa kwedatha njengoba izinga lokushisa lihlanganisa (lisebenzisa inzwa yangaphandle lokushisa), setha ibanga lokungenzi lutho lebhawodi libe ngu-60 mm ukuze lilungiswe, futhi urekhode i-torque/axial force/izinga lokushisa kanye nejika le-engeli. Njengoba kuboniswe kuMfanekiso 8, kungabonakala ukuthi ngokuqhunyiswa okuqhubekayo kwebhawodi, izinga lokushisa likhuphuka ngokuqhubekayo, futhi ukukhuphuka kwezinga lokushisa kungabhekwa njengokuqondile. Amasampula amabhawodi amane akhethelwe ukulinganisa ngamantongomane azikhiyayo. Umfanekiso 9 ubonisa amajika okulinganisa amabhawudi amane. Kuyabonakala ukuthi amajika amane wonke ahunyushwa kwesokudla, kodwa izinga lokuhumusha lihlukile. Ithebula 2 lirekhoda ibanga lapho ijika lokulinganisa lilishintsha liye kwesokudla kanye nezinga lokushisa elikhuphukayo phakathi nenqubo yokuqinisa. Kungabonakala ukuthi izinga lejika lokulinganisa elishintshela kwesokudla ngokuyisisekelo lilingana nokukhuphuka kwezinga lokushisa.

3. Isiphetho kanye nengxoxo

I-bolt ingaphansi kwesenzo esihlangene sokucindezeleka kwe-axial kanye nokucindezeleka kwe-torsional ngesikhathi sokuqina, futhi amandla omphumela walokhu okubili ekugcineni abangela ukuba i-bolt ivune. Ekulinganisweni kwebhawodi, amandla e-axial kuphela ebhawodi aboniswa kwijika lokulinganisa ukuze anikeze amandla okubamba esistimu engaphansi yokubopha. Kungabonakala emiphumeleni yokuhlolwa kuMfanekiso 5 ukuthi, nakuba kuyinadi elizikhiyayo, uma ubude bokuqala buqoshwa ngemva kokuba ibhawodi lizungeziswe ngesandla lafika endaweni lapho selizolingana khona nendawo yokuthwala yepuleti lokucindezela, imiphumela yejika yokulinganisa iqondana ngokuphelele naleyo yenati elivamile. Lokhu kubonisa ukuthi kulesi simo, ithonya le-torque yokuzikhiya ye-nati elizikhiya alinakwa.

Uma i-bolt iqiniswe ngokuqondile ku-nati elizikhiya ngesibhamu sikagesi, ijika lizoshintsha liye kwesokudla lilonke, njengoba kuboniswe kuMfanekiso 6. Lokhu kubonisa ukuthi i-torque yokuzikhiya ithinta umehluko wesikhathi se-acoustic ku-curve yokulinganisa. Qaphela ingxenye yokuqala yejika eshintshelwe kwesokudla, okubonisa ukuthi amandla e-axial namanje awakakhiqizi ngaphansi kwesimo sokuthi ibhawodi linenani elithile lokwelula, noma amandla e-axial mancane kakhulu, alingana nokuthi i-bolt ayizange icindezelwe ngokumelene ne-axial force sensor. Ukwelula, ngokusobala ukwelulwa kwebhawodi ngalesi sikhathi kuwukwelula okungamanga, hhayi ukwelula kwangempela. Isizathu sokwelulwa kwamanga ukuthi ukushisa okukhiqizwa i-torque yokuzikhiya ngesikhathi senqubo yokuqinisa umoya kuthinta ukusakazwa kwamagagasi e-ultrasonic, abonakala ejikeni. Kubonisa ukuthi ibhawudi lenziwe lide, okubonisa ukuthi izinga lokushisa linomthelela kumagagasi e-ultrasonic. Emfanekisweni wesi-6, i-nati elizikhiya lisetshenziselwa ukulinganisa, kodwa isizathu sokuthi ijika lokulinganisa lingaguquki liye kwesokudla ukuthi nakuba kukhona ukungqubuzana lapho kufihlwa ku-nati elizikhiya, ukushisa kuyakhiqizwa, kodwa ukushisa kufakiwe ekurekhodweni kobude bokuqala bebhawodi. Isuliwe, futhi isikhathi sokulinganiswa kwebhawudi sifushane kakhulu (imvamisa singaphansi kwama-5s), ngakho-ke umthelela wezinga lokushisa awuveli kwijika lesici sokulinganisa.

Kungabonakala ekuhlaziyweni okungenhla ukuthi ukungqubuzana kwentambo ku-screwing yomoya kubangela ukuthi izinga lokushisa lomshudo likhuphuke, okunciphisa isivinini samagagasi e-ultrasonic, okubonakala njengokuguquguquka okuhambisanayo kwejika lokulinganisa ukuya kwesokudla. I-torque, kokubili okuhambisana nokushisa okukhiqizwa ukungqubuzana kwentambo, njengoba kukhonjisiwe kuMfanekiso 10. Kuthebula lesi-2, ubukhulu bokushintsha kwesokudla kwejika lokulinganisa kanye nokwenyuka kwezinga lokushisa kwebhawodi phakathi nayo yonke inqubo yokuqinisa kubalwa. Kungabonakala ukuthi ubukhulu bokushintshwa kwesokudla kwejika lokulinganiswa buhambisana nezinga lokushisa elikhuphukayo, futhi linobudlelwano bokulinganisa bomugqa. Isilinganiso sicishe sibe ngu-10.1. Uma sicabanga ukuthi izinga lokushisa likhuphuka ngo-10°C, umehluko wesikhathi se-acoustic ukhuphuka ngo-101ns, ohambisana namandla e-axial angu-24.4kN ku-M12 ijika lokulinganiswa kwebhawudi. Ngokombono womzimba, kuchazwa ukuthi ukwanda kwezinga lokushisa kuzobangela ukuthi impahla ye-resonant ye-bolt material ishintshe, ukuze isivinini se-ultrasonic wave ngokusebenzisa i-bolt medium sishintshe bese sithinta isikhathi sokusabalalisa kwe-ultrasonic.

4. Ukusikisela

Uma usebenzisa i-nati evamile futhii-nati elizikhiyaukulinganisa ijika lesici lebhawodi, kuzotholakala amajika esici sokulinganisa ahlukene ngenxa yezindlela ezahlukene. I-torque eqinisayo ye-nati elizikhiya inyusa izinga lokushisa lebhawodi, okwandisa umehluko wesikhathi se-ultrasonic, futhi ijika lesici sokulinganisa elitholiwe lizoshintshela kwesokudla ngokuhambisana.

Ngesikhathi sokuhlolwa kwaselabhorethri, ithonya lokushisa kugagasi le-ultrasonic kufanele liqedwe ngangokunokwenzeka, noma indlela efanayo yokulinganisa kufanele yamukelwe ezigabeni ezimbili zokulinganisa amabhawodi kanye nokuhlolwa kwe-axial force.

Isikhathi sokuthumela: Oct-19-2022